| Custom specifications are available. | |

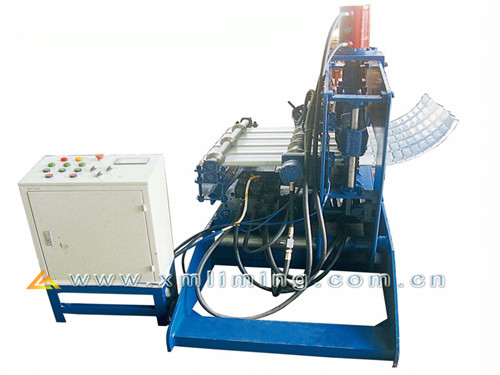

| Operating System | Lanteky operating system in both Chinese and English |

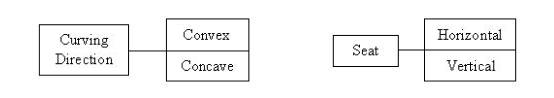

| Frame design | Type 1: horizontal Type 2: vertical |

| Main motor power | 11kW with reducer |

| Power | Electric |

| Electric Standard | 380V /50HZ/3PH or as per customer requirements |

| PLC | Siemens |

| Touch Screen | Siemens |

| Inverter | Schneider |

| Encoder | Omron |

| Contact our sales team for more information. | |

Classification:

Our curving machines can be classified by the following ways into following categories:

Payment:

30% TT before production, 70% TT before shipping.

Packaging and shipping:

Load the container, fix in the items, and then ship by sea.

30% TT before production, 70% TT before shipping.

Packaging and shipping:

Load the container, fix in the items, and then ship by sea.

1. Operating: Stand station with operating system for normal operation, and small controller with long cable for repair and adjustment.

2. Manufacture: Most staff with more than 10 years’ experience.

3. Control hardware: Siemens, Panasonic, etc.

4. Electric components: Schneider.

5. Hydraulic components: Some from China leading factories, and some from Germany.

6. Service: Skilled engineers can fly to any country as required.

Functions:

1. Automatic electrical control.

2. Consecutive multi-radians are available in one piece of profile by inputting all the curving radiuses, arc lengths into the touch screen and tapered angle will be automatically obtained from calculating front/back width and profile length.

3. These curving machines can take on width/angle/radian revising functions of the control system for easy adjustment and use.

Services:

Lanteky warranties its crimping machines for a period of one year from the date of machine leaving our factory, if properly operated and maintained and used under normal conditions.

Installation:

If installation is needed, Lanteky will dispatch technician to the buyer’s factory abroad to assist in installing and commissioning the machine free of charge, but the buyer will be responsible for assisting in Lanteky technician to get the visa, and paying for the roundtrip air ticket, accommodation and local transportation.

2. Manufacture: Most staff with more than 10 years’ experience.

3. Control hardware: Siemens, Panasonic, etc.

4. Electric components: Schneider.

5. Hydraulic components: Some from China leading factories, and some from Germany.

6. Service: Skilled engineers can fly to any country as required.

Functions:

1. Automatic electrical control.

2. Consecutive multi-radians are available in one piece of profile by inputting all the curving radiuses, arc lengths into the touch screen and tapered angle will be automatically obtained from calculating front/back width and profile length.

3. These curving machines can take on width/angle/radian revising functions of the control system for easy adjustment and use.

Services:

Lanteky warranties its crimping machines for a period of one year from the date of machine leaving our factory, if properly operated and maintained and used under normal conditions.

Installation:

If installation is needed, Lanteky will dispatch technician to the buyer’s factory abroad to assist in installing and commissioning the machine free of charge, but the buyer will be responsible for assisting in Lanteky technician to get the visa, and paying for the roundtrip air ticket, accommodation and local transportation.

Tag: Hydraulic Arc Crimping Machine | Hydraulic Roofing Sheet Crimping Machine | Arc Sheet Curving Machine | Roof Sheet Crimping Machine

English

English Russian

Russian Spanish

Spanish French

French Arabic

Arabic Portuguese

Portuguese