|

All details could be

customized.

|

|

|

Operating

System |

Lanteky operating system in both Chinese and English |

|

Frame

design |

Type 1 Wall-plate-frame-design Type 2 New-stand-frame-design |

|

Main motor power |

11KW with reducer |

|

Driven |

Chain and Gear |

|

Max.

Line speed of roll former |

15m/min (Higher speed is available, depends on the specification

required by the buyer) |

|

Hydraulic

group power |

4KW |

|

Electric

Standard |

380V /50HZ/3PH or as the customer's requirements |

|

PLC |

Siemens |

|

Touch

Screen |

Siemens |

|

Inverter |

Schneider |

|

Encoder |

Omron |

|

Accessory

Option |

1. Un-Coiler/De-Coiler 2. Hydraulic pre-shearing device 3. Stacker 4. CE certificate |

|

Please contact with sales to get much more information. |

|

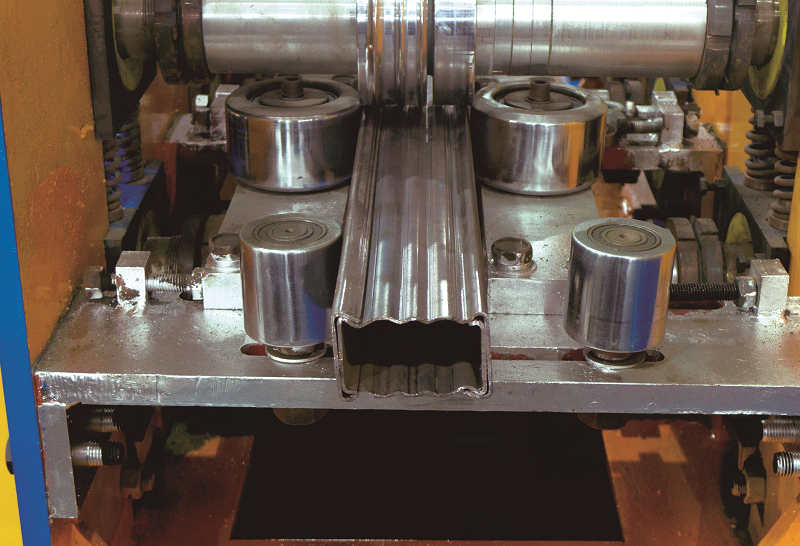

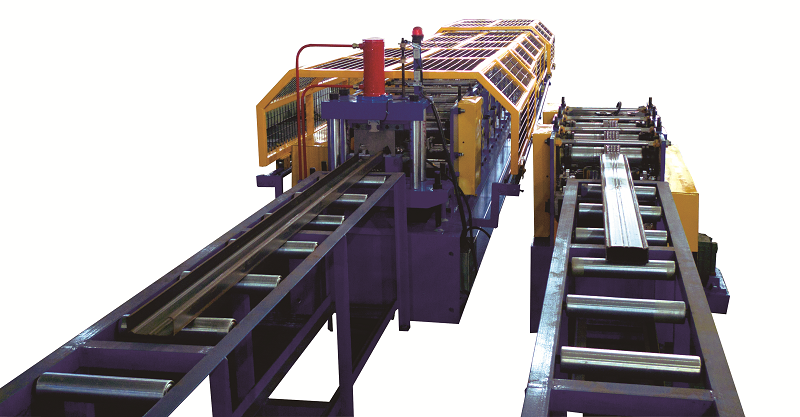

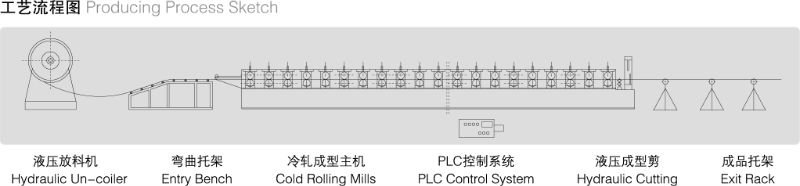

It’s composed by

two machines, one for forming, the other to press two sheets together to be a

cross beam.

Operating: Controlling carbinet with PLC

and Touch Screen

Manufacture: Most Staff experienced more than 10 years

Control Hardware: Siemens

Electric Component: Schneider or same grade

Hydraulic Component: Some from China leading factories, and some from Germany

Service: Skilled engineers can fly to any country as required

Warranty: One year since leaving our factory if properly operated and maintained, electric elements excluded

Manufacture: Most Staff experienced more than 10 years

Control Hardware: Siemens

Electric Component: Schneider or same grade

Hydraulic Component: Some from China leading factories, and some from Germany

Service: Skilled engineers can fly to any country as required

Warranty: One year since leaving our factory if properly operated and maintained, electric elements excluded

Payment: 30% TT before production, 70% TT

before shipping.

Packing: Load into container and fixed in container directly

Shipping: FCL by Sea

Packing: Load into container and fixed in container directly

Shipping: FCL by Sea

Tag:

English

English Russian

Russian Spanish

Spanish French

French Arabic

Arabic Portuguese

Portuguese